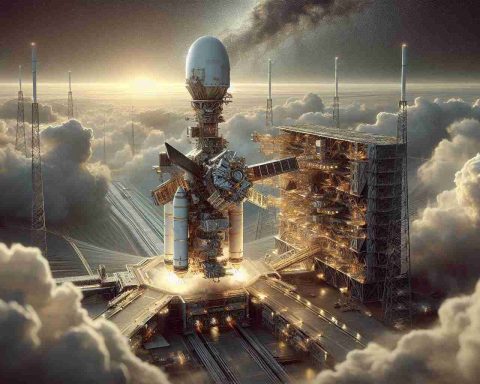

An Italian aerospace company has recently inaugurated a cutting-edge manufacturing facility, marking a significant step towards revolutionizing space manufacturing and exploration. The event, graced by esteemed officials, highlighted the company’s commitment to advancing technology and expanding its operations across Europe and the United States.

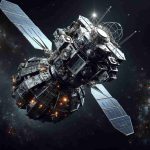

The newly unveiled facility, known as SpaceHub, boasts a futuristic design reminiscent of a sci-fi spaceship, setting it apart as a beacon of innovation in the industry. The company’s CEO expressed his enthusiasm for the unique building, emphasizing the decision to repurpose existing infrastructure to minimize environmental impact and embrace a sustainable approach to growth.

The company’s strategic vision includes fostering a collaborative ecosystem through SpaceHub HUB, an accelerator program aimed at supporting startups in developing cutting-edge technologies for spacecraft. By nurturing emerging talent and enhancing product capabilities, the company aims to propel the space industry towards new frontiers of exploration and discovery.

With a high-tech production capacity of one satellite per week, SpaceHub is poised to undertake groundbreaking projects like advanced Earth observation constellations. The company’s commitment to research and development underscores its objective of achieving self-sufficiency in satellite subsystem manufacturing, with plans for potential future expansions and innovations on the horizon.

By leveraging its facilities in the United States and forging partnerships with government agencies, the company is strategically positioning itself to capture growth opportunities and expand its global footprint. As it continues to embrace innovation and sustainable practices, the company remains at the forefront of space manufacturing, paving the way for a new era of space exploration and discovery.

Revolutionizing Space Manufacturing: Uncovering New Frontiers and Challenges

Amidst the excitement surrounding the inauguration of SpaceHub, there are several critical questions that arise, shedding light on both the opportunities and obstacles in the field of space manufacturing. Let’s delve deeper into the topic to understand the complexities involved and the potential impact on the aerospace industry.

Key Questions:

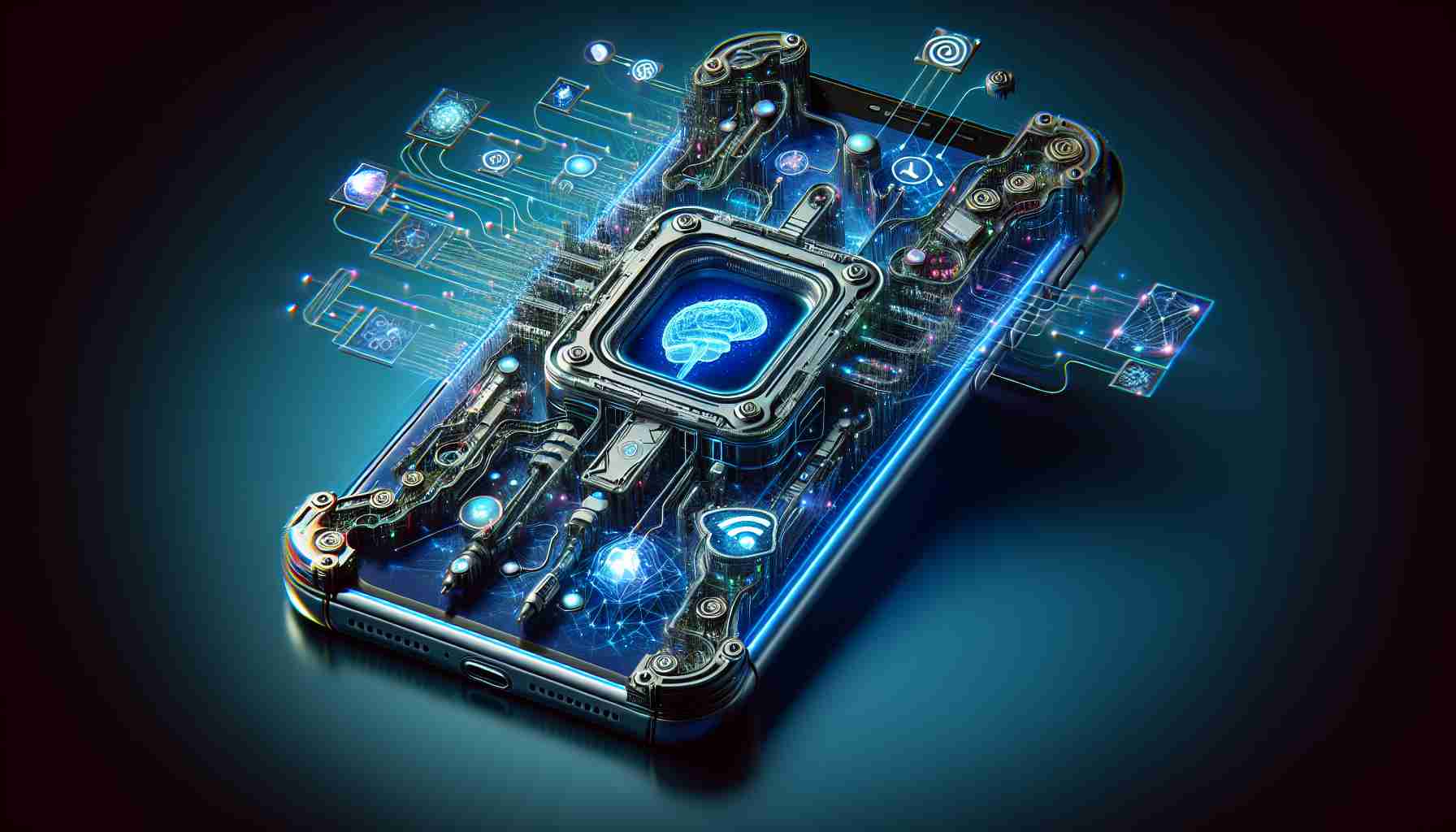

1. How will the integration of AI and automation revolutionize space manufacturing processes?

2. What are the ethical implications of privatizing space manufacturing and exploration?

3. How can space debris management be effectively addressed to ensure sustainable practices in the industry?

Answers and Insights:

– The incorporation of artificial intelligence and automation technologies can significantly enhance production efficiency, reduce human error, and streamline complex manufacturing processes. By embracing these innovations, companies like the Italian aerospace firm can achieve higher productivity levels and superior quality control in the construction of satellites and spacecraft.

– Private companies venturing into space manufacturing raise questions about ownership rights, intellectual property issues, and the potential militarization of space activities. Balancing commercial interests with international regulations and collaborative efforts is crucial to ensuring responsible and peaceful utilization of outer space resources.

– The proliferation of space debris poses a risk to operational satellites and spacecraft, necessitating robust mitigation strategies and regulatory frameworks. Addressing the challenges of debris tracking, removal, and prevention is essential to sustaining the long-term viability of space manufacturing endeavors.

Advantages and Disadvantages:

Advantages:

– Accelerated innovation and technological advancements in space manufacturing processes.

– Enhanced collaboration opportunities among startups, established companies, and research institutions.

– Potential for significant cost reductions and improved scalability in satellite production and assembly.

Disadvantages:

– Regulatory uncertainties and geopolitical tensions may impede the expansion of commercial space manufacturing activities.

– Environmental concerns related to the disposal of space debris and the sustainability of space exploration initiatives.

– Challenges in ensuring data security, privacy, and transparency in the interconnected space manufacturing ecosystem.

As companies strive to revolutionize space manufacturing practices, navigating these complex dynamics and addressing the associated challenges will be imperative for the sustainable growth and development of the aerospace sector.

For further insights into the cutting-edge advancements and trends in space manufacturing, visit NASA’s official website.